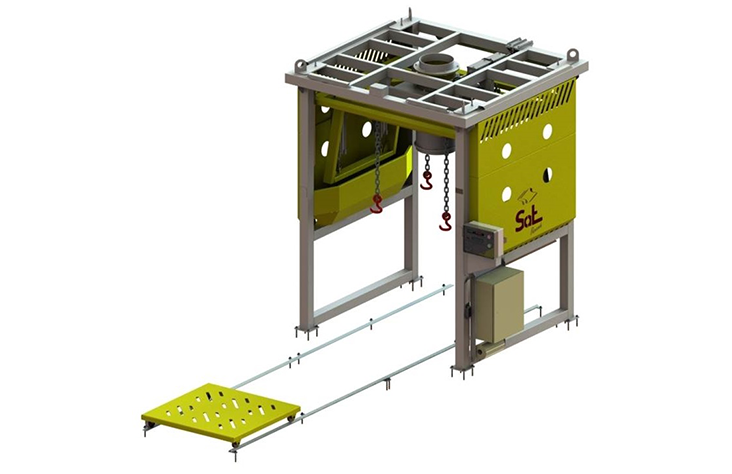

BAGGER BIG-BAG

DIRECT WEIGHING

The Bagging Machine for Big Bags of Direct Weighing (Big Bag PD) is intended to bag any type of solid / granulated / powdery product in sacks of up to 1500 Kg, with direct weighing through load cells.

Applicable in all types of industry, Agroindustry, Food, medicinal, Cosmetics, Refrigerators, Chemicals, etc. and product forms such as Granules, Grains, Seeds , Salt, Sugar, Coffee , Pellets, Extruded, Powdered, Fertilizers, Cement, Acrylic Paste, Stucco, Plaster, Calines, Calcarium, Virgin lime and Hydrated Lime, Mortars, Grouting, Mortar , Food and Powdered or Micronized Chemicals, Plastics, Pigments, Paints, among others.

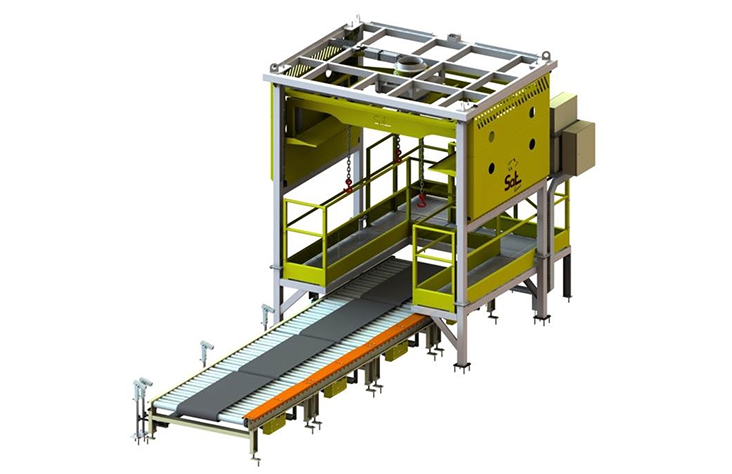

PRE-WEIGHING

The Sat Paraná Pre Weigh BIG BAG Bagger was developed to bag large-scale solid products, in bags up to 2000Kg.

The equipment is composed of two hoppers / silos , one upper and one lower (weighing hopper). The product to be bagged leaves the hopper / silo client ´t main storage to the top hopper / silo of the packing machine, from where it is released into the weighing hopper / silo through the opening of a butterfly valve. The four load cells are responsible for the weighing the product in the lower silo, with a capacity of 2000 Kg. Near reaching the programmed weight, one of the cylinders (duplex), responsible for the opening and closing of the butterfly valve, is activated, partially closing the exiting of the product until the programmed weight is reached. When reaching the programmed weight, the second cylinder is activated, completely obstructing the feed of the weighing hopper . Once the programmed weight is confirmed, the electronic system emits a command fully opening the butterfly valve of the hopper / silo weighing, releasing the product for the bag.

While the product (already weighted) is transferred to the Bag, more product arrives at the hopper / weighing silo , in order to leave the programmed quantity of product ready for the next Bag. This system allows that there is always the right amount of product expected to be bagged, guaranteeing greater agility and a production up to 80 Big-bags per hour.

Applicable in all types of industry, such as Agroindustry, Food, medicinal, Cosmetics, Refrigerators, Chemicals, etc. and product forms such as Granules, Grains, Seeds, Salt, Sugar, Coffee, Pellets, Extruded, Powdered, Fertilizers, Cement, Acrylic Paste, Stucco, Plaster, Calines, Calcarium, Virgin lime and Hydrated Lime, Mortars, Grouting, Mortar , Food and Powdered or Micronized Chemicals, Plastics, Pigments, Paints, among others.

OPTIONAL BIG-BAG:

VIBRATORY TABLE : fixed under the bag´s accommodation tape, posterior of bagging , the vibration enables better arrangement of the product in the bag, especially when it comes to powdery products.

SLIDING CART: located in the center of the bagger, with rails on the floor and platform to be placed under the Bag to be filled. The carriage has the function of manually transport the Bag filled to pallets or storage place according to the customer´s choice. After the end of the bagging process, the operator pulls the cart to the desired location.

MATS FOR AUTOMATIC TRANSPORTATION OF BAGS: located in the center of the bagging, just below the Bag to be filled. The purpose of the mats is to transport the full Bag to the pallets where they will be accommodated in the storage location of the customer's choice. This process is automated, motorized , dispensing the use of force by operators.

Do a search

Talk to us

Contact us via the site to forward your need to the representative.

Avenida Santos Dumont, 1450 - Santo Antônio CEP 89223-003

Joinville - Santa Catarina

Brasil